Expanding Horizons in Construction: ICON’s Vulcan 3D Printer

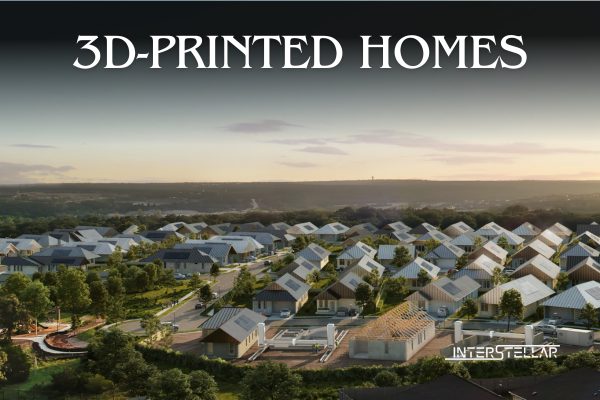

Like any desktop 3D printer, ICON’s Vulcan printer constructs objects layer by layer. However, this is no ordinary printer. The Vulcan is over 45 feet wide, weighs 4.75 tons, and prints residential homes. This summer, the robotic printer is completing the final homes of a 100-house project in Wolf Ranch, a community in Georgetown, Texas, roughly 30 miles from Austin.

Building the World’s Largest 3D-Printed Community

ICON has named Wolf Ranch the world’s largest 3D-printed community. The company began printing the walls of these homes in November 2022. According to ICON, 3D printing homes offers several advantages over traditional construction. The process is faster, more cost-effective, requires fewer workers, and reduces construction material waste.

ICON’s senior project manager, Conner Jenkins, highlighted the efficiency brought to the trade market. “Where there were maybe five different crews coming in to build a wall system, we now have one crew and one robot delivering that scope,” Jenkins explained.

How the 3D Printing Process Works

The printing process begins when concrete powder, water, sand, and other additives are mixed together and pumped into the printer. A nozzle then lays down the concrete mixture layer by layer along a pre-programmed path. It takes approximately three weeks to complete the printing of the single-story homes.

While only the walls are 3D-printed, the foundation and metal roof are traditionally installed by Lennar, a project partner. Another partner, Bjarke Ingels Group, designed eight different floor plans for these homes. The designs range from three to four bedrooms and cover 1,500 to 2,000 square feet.

The concrete walls created by the printer are designed to resist water, mould, termites, and extreme weather, making them a durable option for homeowners.

Homeowners’ Experience in Wolf Ranch

Austin native Lawrence Nourzad, a 32-year-old business development director, purchased one of these 3D-printed homes with his girlfriend, Angela Hontas. “It feels like a fortress,” Nourzad said. He expressed confidence in the home’s ability to withstand extreme weather, including F2 and F3 tornadoes. Nourzad also praised the strong insulation provided by the thick concrete walls, which help maintain a cool interior temperature during the hot Texas summers, even without running the air conditioner at full capacity.

However, these robust walls have also posed a minor challenge. Nourzad mentioned experiencing some connectivity issues with Wi-Fi. “Obviously these are really strong, thick walls,” he said. “That’s what provides a lot of value for us as homeowners, but signal doesn’t transfer through these walls very well.”

Future Prospects and Expanding Ambitions

The 3D-printed homes at Wolf Ranch, collectively known as the “Genesis Collection,” are priced between $450,000 and $600,000. Developers have reported that just over a quarter of the 100 homes have already been sold.

ICON, which printed its first home in Austin in 2018, is now looking beyond Earth. The company has partnered with NASA as part of the Artemis Moon exploration program. NASA has contracted ICON to develop a construction system capable of building landing pads, shelters, and other structures on the Moon’s surface.